• Ext. Dimensions(With Lid): 1200(L) x 1000(W) x 1120(H) mm

• Int. Dimensions: 1120(L) x 920(W) x 965(H) mm

| Item | Ext. Dimensions (With Lid) | Int. Dimensions | Folded Height (With Lid) | Volume |

|---|---|---|---|---|

| PTX-1210G | 1200(L) x 1000(W) x 1120(H) mm | 1120(L) x 920(W) x 965(H) mm | 1200(L) x 1000(W) x 335(H) mm | 1000 L |

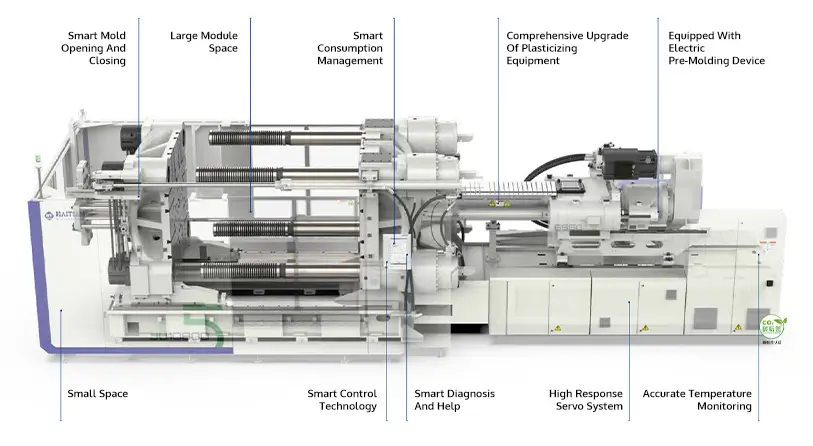

Our company uses the international leading Haitian brand injection molding machine, with a mold locking force of 33000 KN. It can fully meet the production of pallets and IBC(intermediate bulk container) for various purposes in the logistics industry.

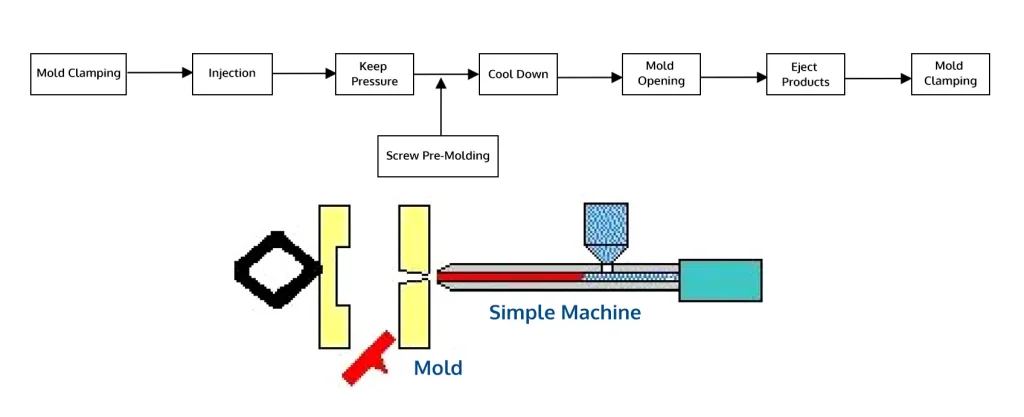

The product is processed by injection molding. The following is the injection molding machine production process flow chart: The injection molding process of the reciprocating screw plastic injection molding machine is as follows:

Our Foldable IBC and Plastic Pallets combine over 18 years of expertise in R&D and manufacturing with a commitment to quality and cost-efficiency.

We leverage professional knowledge of raw materials to ensure top-notch product quality at minimal cost, making our solutions stand out in terms of durability and affordability.

With a rich history of collaborating with numerous transnational corporations, we bring invaluable insights and proven reliability to every project, guaranteeing satisfaction and success.

With a capacity exceeding fifty thousand tons, we are fully equipped to provide a cost-saving service without compromising on quality or quantity.

Yes, our high investment in research ensures a diverse range of products tailored to meet the unique requirements of various customers, ensuring satisfaction across different industries and applications.

Absolutely. Our products are recyclable, reflecting our commitment to sustainability and reducing environmental impact, making them an eco-conscious choice for businesses seeking greener solutions.

Rest assured, LISHI prides itself on delivering credible quality, backed by stringent quality control measures and a dedication to excellence in every aspect of production.

Certainly! We offer personalized services to meet specific requirements, ensuring that each client receives tailored solutions that perfectly align with their needs and preferences.

Copyright © LISHI Inc. 2005 – 2024