Home » Pallets

Plastic pallets are a type of pallet made from plastic materials rather than traditional wood or metal. They are used for the storage and transportation of goods in various industries such as logistics, warehousing, manufacturing, and retail. Plastic pallets offer several advantages over their wooden or metal counterparts, including durability, resistance to moisture, chemicals, and pests, as well as being lightweight and easy to clean. They come in different sizes, designs, and configurations to accommodate different types of goods and handling equipment.

Information resources on shelf-ready plastic pallet types, specifications, applicable industries and supporting product introductions. Learn about usability, benefits, technology, and more.

LISHI is a leader in the field of reusable plastic packaging, offering a variety of customized solutions to meet different logistical needs. As a major supplier of plastic pallets, we provide robust and reliable solutions for storing and transporting commercial goods, plastic packaging, chemicals, and more. With over 18 years of industry expertise, we have a rich inventory, including various specifications and models of plastic pallets to choose from, consistently exceeding customer expectations whenever possible. Our comprehensive knowledge covers all major industries and products, enabling us to match you with the perfect pallet to meet your specific requirements.

LISHI’s plastic pallets are versatile and suitable for a variety of industries, including:

Lightweight, stable, durable and 100% recyclable

Made of HDPE and PP and recycled HDPE and PP

Regular testing is performed using specialized machinery to ensure product performance standards.

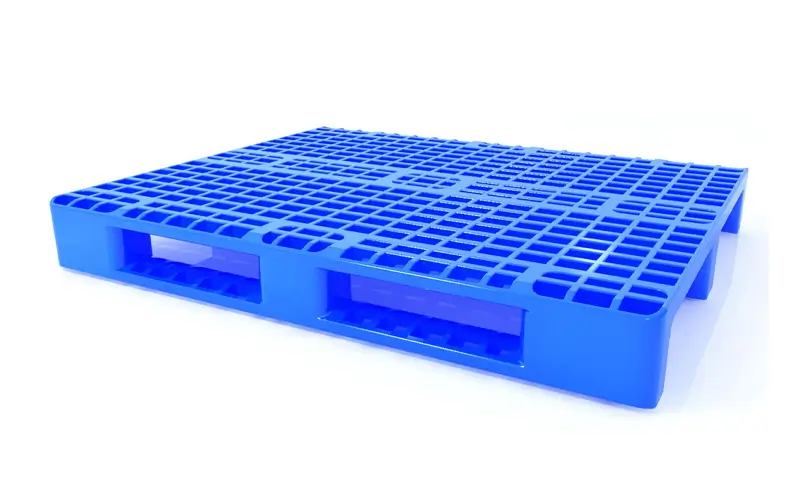

Single-sided plastic pallets are designed with only one side for storing goods, typically used for light-weight goods or situations where goods need to be accessed from one direction only. Their simple design makes them suitable for environments with limited space or where easy handling is required. The advantages of single-sided pallets include their lightweight nature, cost-effectiveness, and ease of cleaning and maintenance.

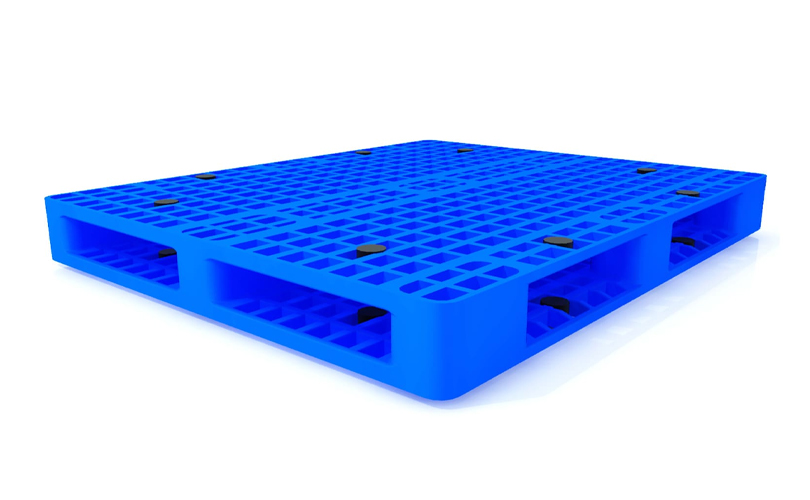

Double-sided plastic pallets feature storage surfaces on both sides, allowing for goods to be accessed from both directions. These pallets are commonly used in situations that require frequent handling, bidirectional access to goods, or enhanced storage efficiency. Their dual-sided design offers greater flexibility and efficiency, as well as durability and stability, making them suitable for various environments and logistical needs.

Plastic pallets have several advantages over wooden pallets:

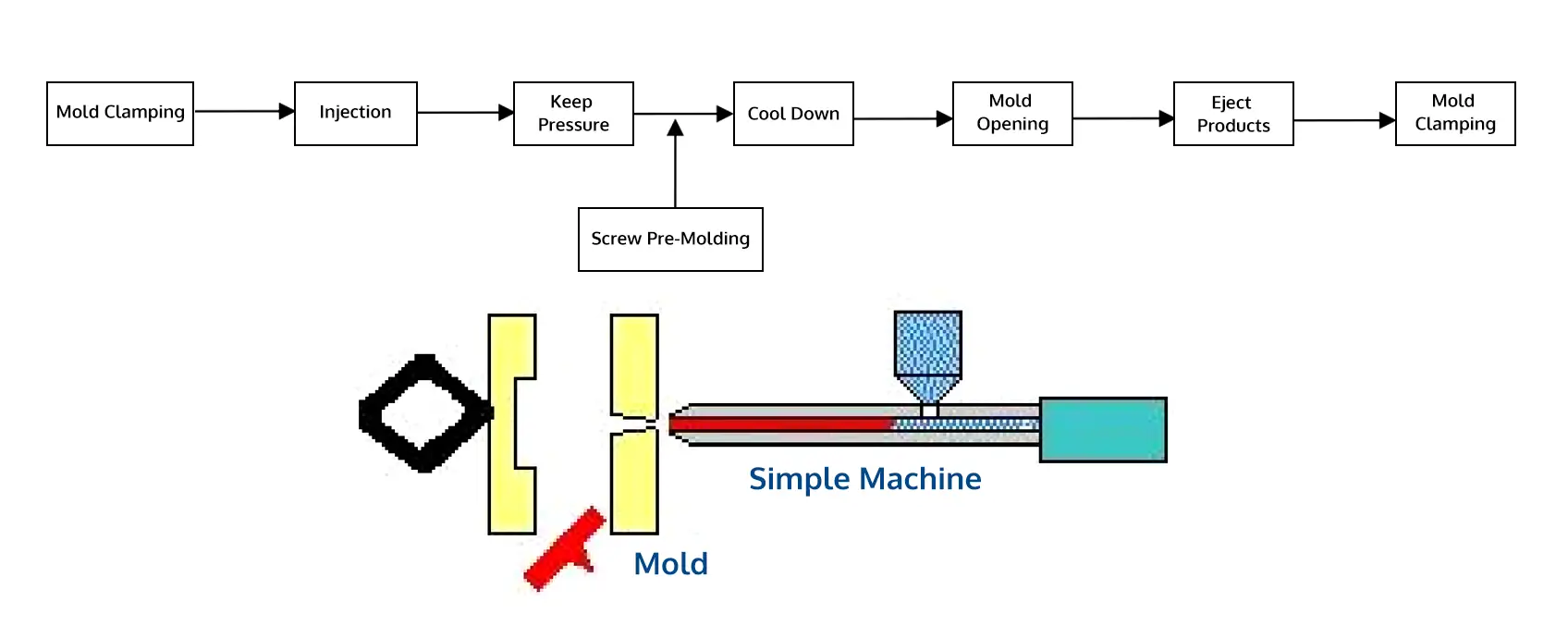

Our company uses the international leading Haitian brand injection molding machine, with a mold locking force of 33000 KN. It can fully meet the production of pallets and IBC(intermediate bulk container) for various purposes in the logistics industry.

The product is processed by injection molding. The following is the injection molding machine production process flow chart: The injection molding process of the reciprocating screw plastic injection molding machine is as follows:

With high investment in research, we have various products to meet the needs of different customers.

Customized service available. Please consult us for details!

At LISHI, we take pride in offering prompt quotes and comprehensive customer service, empowering you to make informed decisions swiftly. Located in Shanghai, we ensure swift shipping of our cutting-edge products, delivering your plastic pallets within days. Once your order is placed, trust our professional customer service team to provide you with ongoing assistance.

For further details on our Plastic Pallets or to request a quote, contact LISHI today. We’re here to address your inquiries and provide you with the information you need.

“We recently switched to LISHI’s plastic pallets, and the difference has been remarkable. Not only are they sturdy and reliable, but the team at LISHI also provided excellent support throughout the process. Highly recommended!”

— Maria Lopez, Warehouse Manager, Spain

Copyright © LISHI Inc. 2005 – 2024